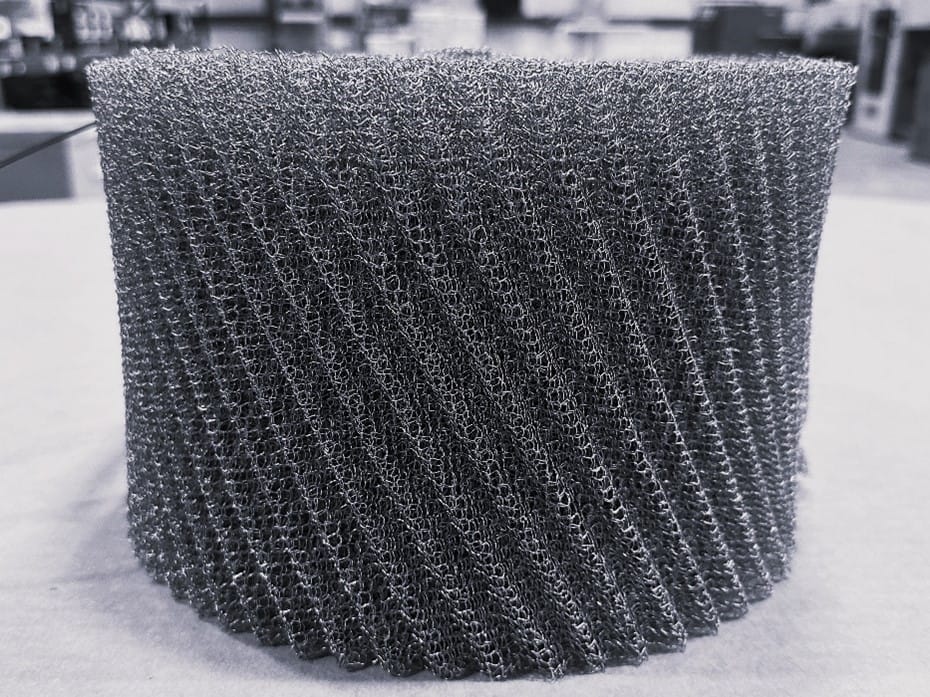

All wells are affected by sediment that requires screening before entering well pipes. In extreme cases, the liquid being extracted can create harsh conditions that lead to corrosion of the screening material.

Well screen manufacturers require a wire that can be shaped to filter out sediment while also fighting against the corrosion that can damage screens and render them ineffective, resulting in expensive repairs.

At Loos and Co., Inc. We manufacture wire that can be shaped for creating the ultimate screening capabilities while also being able to withstand the harshest downhole conditions.

Available Alloys

There are various alloys available for use in our Well Screen Wire, to ensure the demanding conditions of its applications can be met. Stainless Steel options such as 302/304 and 316, as well as Nickel options such as Inconel® 625, Incoloy® 825 and Monel®

For questions about alloy selection or custom material options, contact our sales team at sales@loosco.com.

Applications

The main application of our Well Screen Wire is as a filter, eliminating the sediment present in well pipes and limiting the potential damage caused by it. Preventing expensive repairs and the loss of valuable extraction time are a few of the benefits that our Well Screen Wire helps provide.