Sustainability with Renewable Energy

Renewable energy sources require reliable materials with resistance to the environmental challenges they face. Malfunctions within renewable energy plants or fields means lost money, wasted time and outages for those being provided with energy.

Below are the applications of our product lines in renewable energy.

Product Lines

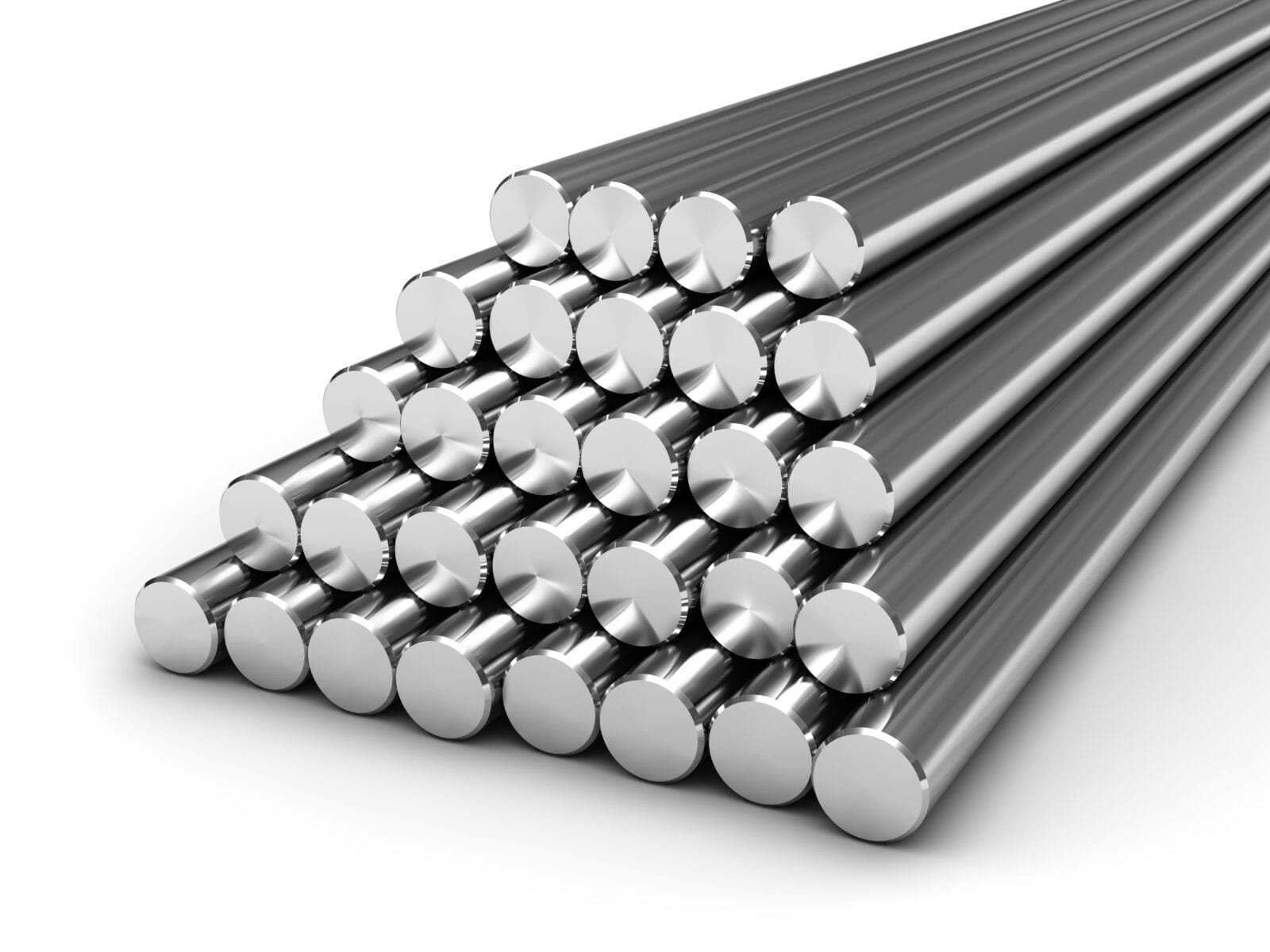

Bar Stock

Premium stainless steel and nickel bar stock manufactured up to 0.750” to customer specifications. Highly customizable for many end-use applications and mission critical industries.

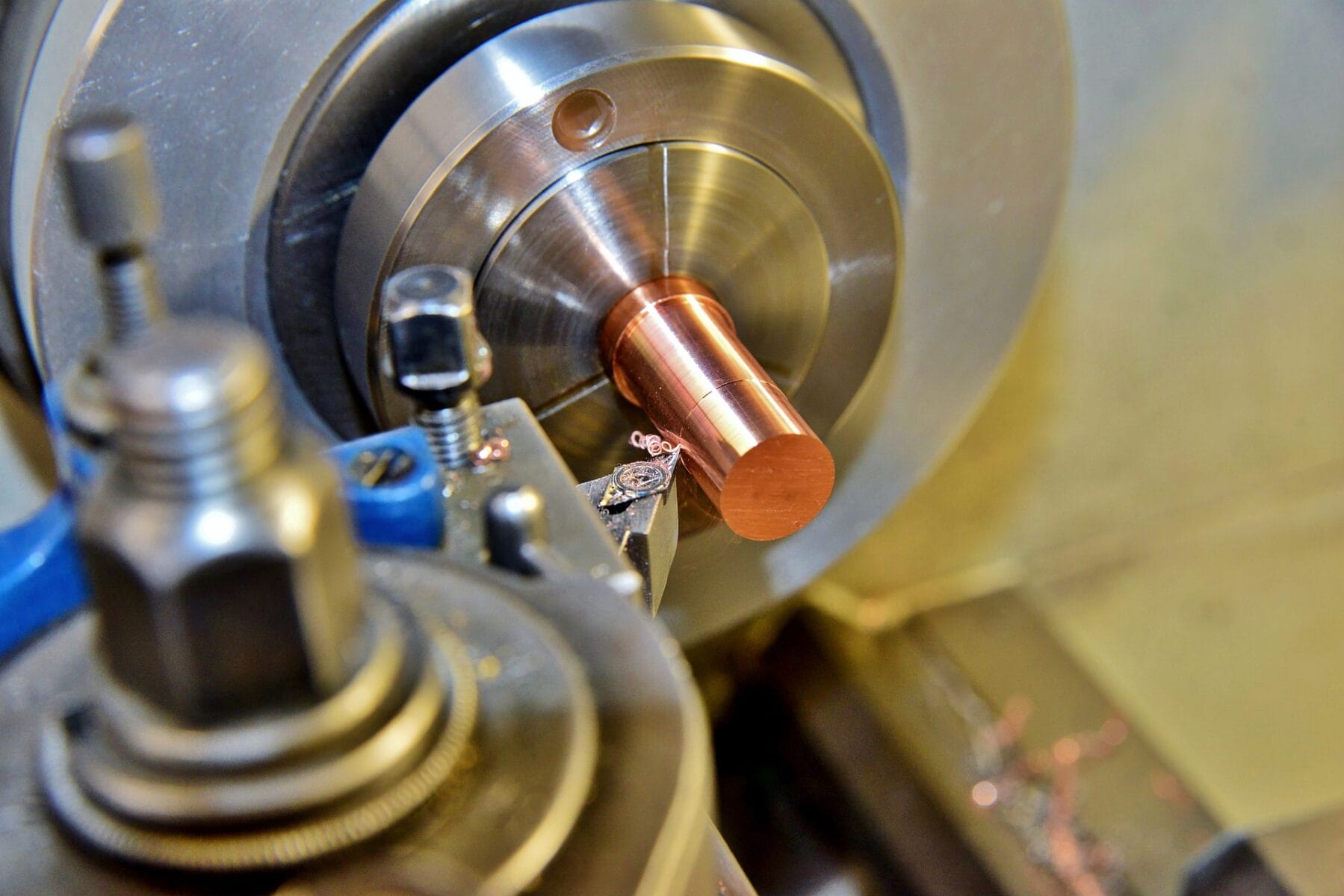

CNC Machining

Custom CNC manufacturing can use many different alloys including stainless steel, aluminum, brass, bronze, copper and nickel. Custom parts are tested in-house to ensure quality, and precise machining produces the perfect product every time.

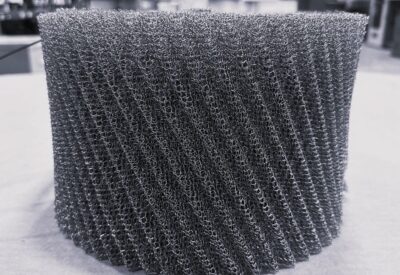

Demister Pads

Custom demister pads manufactured in shapes including round, rectangle, ring and custom. Strong grid structure and ductility capabilities allow for consistent mist elimination.

Knitted Wire Mesh

Wire filter mesh made from individual wires that are interlaced, or knitted, together. Loops are strategically woven to be able to move and stretch, with flexibility and durability to handle harsh applications

Shaped Wire

Available in stainless, duplex, nickel, copper, brass and carbon alloys, our shape wire is custom manufactured in house to fit specific customer needs. The profile wire sizes we offer are 1.25mm² to 150mm ² CSA (Cross Sectional Area).

Welding Wire

Welding wire produced for various techniques including MIG, TIG and SAW welding. Available in stainless and nickel-based alloys.

Renewable energy sources require reliable materials with resistance to the environmental challenges they face. Malfunctions within renewable energy plants or fields means lost money, wasted time and outages for those being provided with energy.

Below are the applications of our product lines in renewable energy.

Product Applications

Turbine/Solar Repair

As in all welding applications, quality welds and proper material and technique choice are essential for durable construction and repairs. The renewable energy industry offers different challenges, with harsh weather and high mechanical loads putting more stress on materials.

Our welding wire performs when the highest levels of quality and safety are required and produces welds that can withstand this industries harshest challenges.

Liquid-Gas Filtration

In hydropower energy applications, quality filtration is required for the best results. Our knitted wire mesh and custom demister pads remain consistent in liquid-gas separation applications. Impurities and mist droplets are separated, ensuring purity of the hydrogen and maintaining efficiency and performance within the filtration device.

Demister pads can also be used in wind turbines to separate any entrained moisture or droplets from the airflow, ensuring only dry air enters the system.

Structural Parts

Bar stock, CNC machining and shaped wire can all be involved in the structural components of turbine, solar and hydro energy machinery.

Components such as shafts, bearings, hubs, fasteners, and other small parts must be able to handle both the environmental challenges and high mechanical loads of these applications.

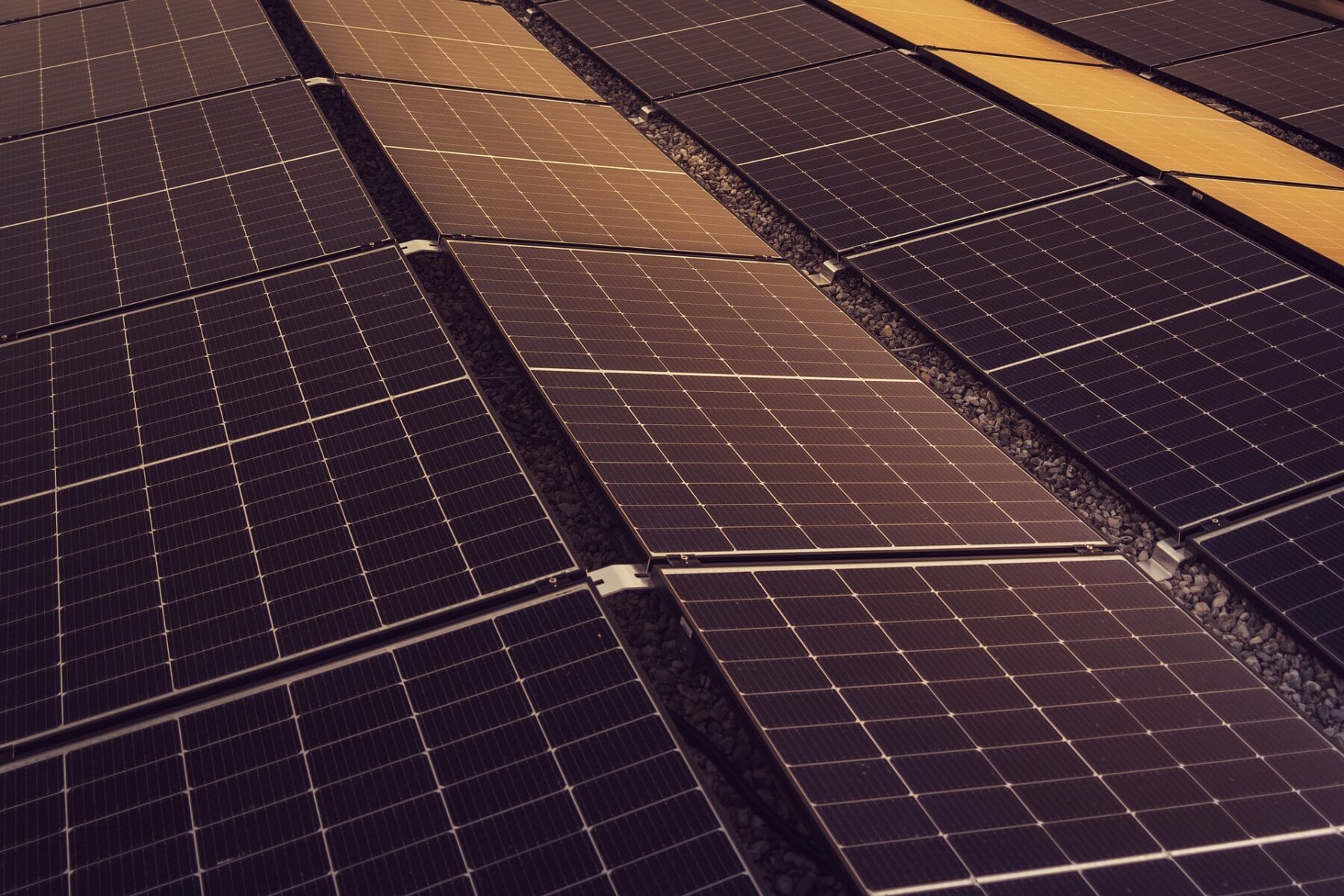

Solar Tracking

Solar tracking systems are essential to producing solar energy, as they orient solar panels or mirrors to maximize sunlight exposure throughout the day. Without them, there would be times during the day when solar panels are not as effective as desired in producing energy.

Bar stock alloys are often employed in the framework and mechanical components of these systems, to provide stability and durability.