Mining Safety and Production

Mining is an industry with various environmental and safety concerns, from ensuring worker safety to having quality machinery to limit physical exertion in a high-labor industry.

Below you can see our product lines that cater to the industry and some of the applications of our products in mining.

Product Lines

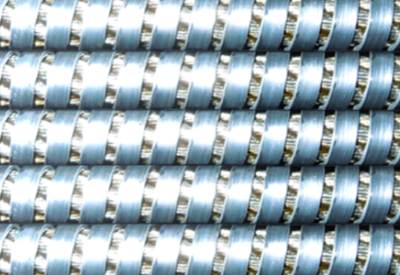

Durable cables with metal shielding that can withstand harsh conditions, extending usage life and allowing abrasion resistance. Sizes range from 1/16” to 5/16”.

Custom cable assemblies crafted with precision and expertise. Our aircraft, military, and commercial cable assemblies are all highly customizable, and are durable enough to withstand demanding applications.

Manufactured with Lolon® coatings setting the standard for durability and reliability in the conveyor industry. High quality conveyer cables ensuring minimal downtime and maximum efficiency.

Safety light reflective wire rope that provides a visual barrier for outlining hazards in any application. Reflexlite® has a 1/8” wide strip of reflective material creating a series of silver-white dashes visible from several hundred feet away.

Lighting to improve visibility and safety, and hoists to successfully move heavy machinery into mines are just two of the ways we serve the mining industry.

Here are some of the applications of our products in mining, helping improve safety and efficiency.

Product Applications

Mine Safety Lighting

Our Reflexlite® cable can be used for various hazards and is very effective in the mining industry. This industry offers countless hazards, and most if not, all are difficult to see in dark, underground mining settings. Mine safety lighting can allow dangerous machinery, chemical hazards and explosive hazards to be visible, ensuring safety for workers in the harsh conditions the industry presents.

Mine Hoists

Many items that are transported up and down mining sites are extremely heavy, from large machinery to various ores and minerals. Our armor wrapped cable is ideal, with the metal shielding offering more durability and strength for these hoisting applications. The heavy-duty shield also offers additional abrasion and corrosion resistance, leading to less wear and tear or even malfunction risks. Along with these robust material hoisting applications, miners themselves often use cables to enter and exit mine sites, so a cable that ensures safety is required.

Mine Conveyor Belts

To reduce physical exertion and improve efficiency in mining sites, conveyor belts are used to transport ore, coal, or waste rock from one location to another. These belts require durable and strong conveyer cables, as large loads of mining materials can be very heavy. These systems also require emergency stop functions, in case of any safety risks or system malfunctions that jeopardize the safety of miners. Our reliable Canveyor® conveyer cable is perfect for this application, as strong materials and durable coatings allow for robust and consistent performance.