It’s not just our adherence to quality standards that sets us apart; it’s also our capabilities. Whatever your application, we provide products for a variety of applications, and some of our capabilities include engineering, testing & inspection, manufacturing, prototyping, and the use of a wide range of materials.

If you have a project in mind, we have a very skilled engineering team who are willing to meet you at your level and provide exactly what your application requires. Our testing and inspection process guarantees that you receive the highest possible quality product, every time.

We are an industry leader in Mil-Spec hardware, but our capabilities go beyond this. We offer a host of machining capabilities and turnkey services that aren’t common at your average machine shop, including high-capacity thread-rolling, presses from 15 to 500 tons, plating, coating, heat treating, powder-coating, bead blasting, packaging, custom cable assembly, expedited service, penetrant inspection, magnetic particle inspection, annealing, and in-house passivation (per ASTM A967 standards).

Engineering

Our engineering and production capabilities allows us to offer a diverse range of precision parts to suit your needs, catering to a wide array of industries, including Aerospace, Electronics, Industrial, Medical, and Military. Our team of engineers are available to work directly with you in order to ensure all of your needs are met, and that only the highest possible product is rendered for you.

Loos Precision Products uses the expertise of our staff of engineers to increase the rate of production output by utilizing an array of techniques central to manufacturing. Accuracy and durability are always at the fore, and we adhere to your distinct requirements in the materials selection process, and provide you with engineering support every step of the way.

We have a wide range of available materials and specialize in capabilities not found in your typical machine shop, including high-capacity thread-rolling, presses from 15 to 500 tons, powder coating, in-house passivation, mechanical and cable assembly, heat-treating, and plating services.

We have the technical knowledge to ensure all of your product needs are met, and expectations exceeded. We pride ourselves on our ability to offer engineering support as pertaining to your specific application. You can expect prompt quotations and expert advising from our engineering team always.

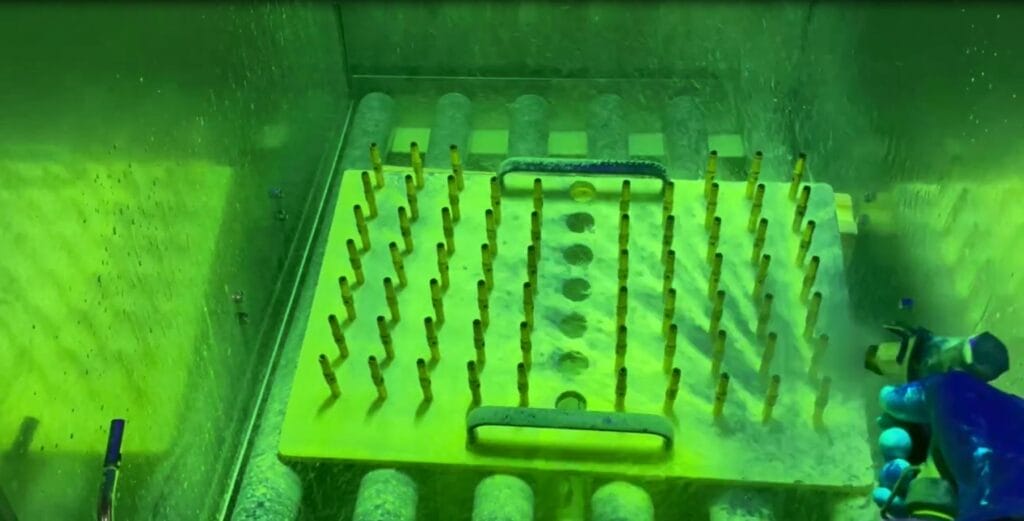

Testing & Inspection

Testing and inspection are crucial components at Loos Precision Products. We want to ensure that all our machines and products are constantly performing at their best to adhere to the unique requirements of our clients’ needs. All our machines are consistently maintained to guarantee reliable, maximum manufacturing potential.

Loos’ Quality Control department is committed to maintaining a level of consistency on par with our certifications in the way we rigorously inspect each lot that moves through our facility. Certified to AS9100D and ISO 9001:2015 and QPL/QPM listed for a number of Mil-Spec components, you can be certain you are receiving materials that are carefully inspected to guarantee a product of the highest quality and durability.

We thoroughly test and inspect various aspects of your product, including hardness testing and surface roughness testing. This means you can be certain you are receiving a product that will hold up over time, no matter your application.

Our Testing/Inspection Equipment and Practices Include:

Fluorescent Penetrant Inspection

Production Trends

Surface roughness testing

Hardness testing of steel and aluminum

Crack, weld flaws, and other defect detection

Statistical analysis & process capability (CP & CPK)

Hardness testing of steel and aluminum

Functional tension, compression, and elongation testing

Manufacturing

At Loos Precision Products (LPP), our manufacturing capabilities lie within the realm of custom machine manufacturing. We are able to meet all your immediate and future machining needs.

We have the latest Swiss machine technology and 4-Axis Vertical Mills, and the capability to meet and maintain tolerances as small as .0001”. We are prepared to handle your next project with our wide array of Loos machines that we employ to get the job done right:

- 13 Citizen and Star Swiss Turning Machines all equipped with 12-foot bar feeders and fire suppression to support extended “Lights Out” operation

- 4 Haas CNC Turning Machines with 12-foot bar feeders

- 7 Haas Vertical Mills (some with 4-axis capabilities) with table capacities to X: 30in / Y: 16in / Z: 20in

- 6 Presses ranging from 15 to 500 Ton capacity

- 2 High volume thread rolling machines

- Numerous manual mills, lathes, grinders, etc.

- In-house Powder Coat line

One element of our success is the superior equipment we utilize regularly – maintaining consistent, repeatable, and exact part manufacturing requires that we keep our equipment running at its best. This is why we have a Total Production Maintenance program (TPM) which ensures all our Loos machines are maintained regularly so that we are able to achieve reliable, maximum custom machine manufacturing potential.

Materials

At Loos Precision Products we manufacture custom machined hardware in a wide variety of materials. Whether you need a 300 series stainless steel option, or a high strength option like titanium, we have a solution available for your specific application. Our standard list of materials is available below. If you are looking for an exotic metal, plastic, or phenolic, our knowledgeable team is available to discuss your needs.